PVDC-coated Polyamide Film

Good gas, moisture and aroma barrier properties

Robust barrier coat even under high

humidity

and physical stress

High affinity of coated surface for various adhesives

Comparison of DCR

with other barrier films

| Condition | DCR | Post PVDC-coat BOPA | Multilayer BOPA (MXD) | Standard BOPA (ON) | |

|---|---|---|---|---|---|

| OTR cc/m²·d·atm |

20˚C × 65%RH | 7 | 9 | 8 | 25 |

| 20˚C × 90%RH | 8 | 10 | 18 | 80 | |

| WVTR g/m²·d |

40˚C ×90%RH | 15 | 16 | 100 | 260 |

| Aroma barrier | - | excellent | excellent | poor | poor |

Preservation test

(Paprika pickles)

| Immediately after boil | 4 weeks later | |||||

|---|---|---|---|---|---|---|

| ON | DCR | MXD | ON | DCR | MXD | |

| 20˚C 65%RH |  |

|

||||

| 40˚C 90%RH |  |

|

||||

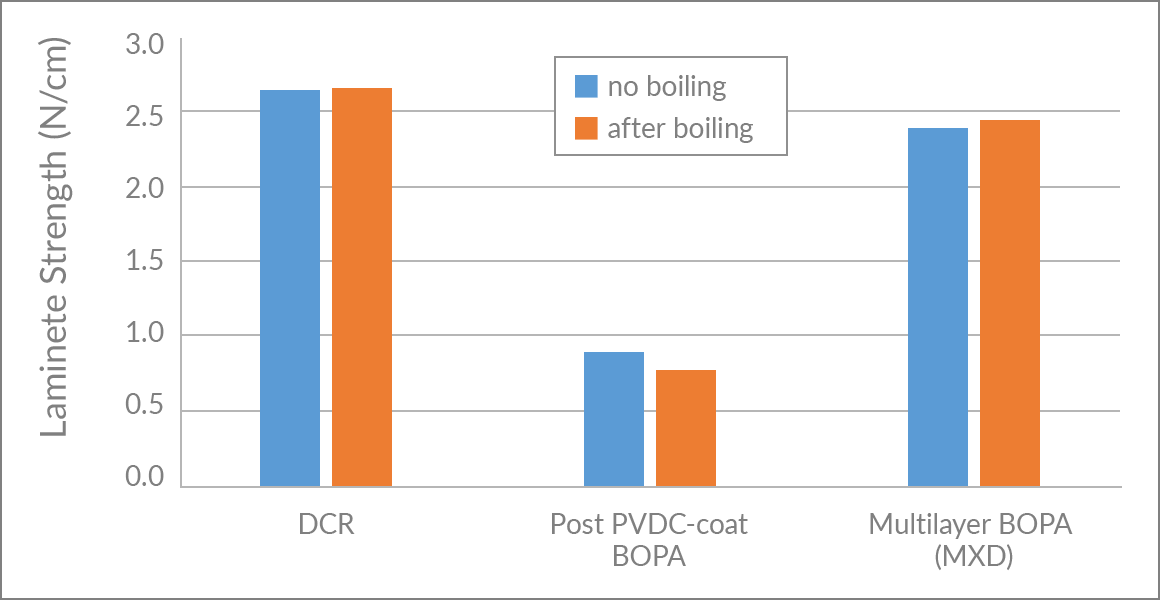

Laminate strength comparison

This data is for informational purposes only, and not a guarantee of the properties of all products.

Before using this film for production, please conduct a test using practical conditions and contents.

Application

- Pouch with O2 barrier

- Ex.Cheese, Processed meet (Ham, Sausage …), and so on.

- Pouch with moisture barrier

- Ex.Baked cakes(Madeleine, Baumkuchen …), and so on.

- Pouch with aroma barrier

- Ex.Spice, Miso, Curry paste, Pickles, and so on.

| Grade | Treatment | Intended use | |

|---|---|---|---|

| Inside | Outside | ||

| DCR | Coat | - | Out layer |

| DCS | Corona | Coat | Middle layer in multi-layer structure |