U polymer

T series resins (transparent high heat resistant grade)

T series have a glass transition temperature(Tg) of maximum 265°C, and it also has a high transparency which can not be seen in other resins."T-200" is capable of lead free reflow soldering depending on conditions, and it maintains its high transperancy throughout the reflow soldering.It is suitable for injection molding and is expected to be applied to all kinds of optical devices.

Approaching Applications

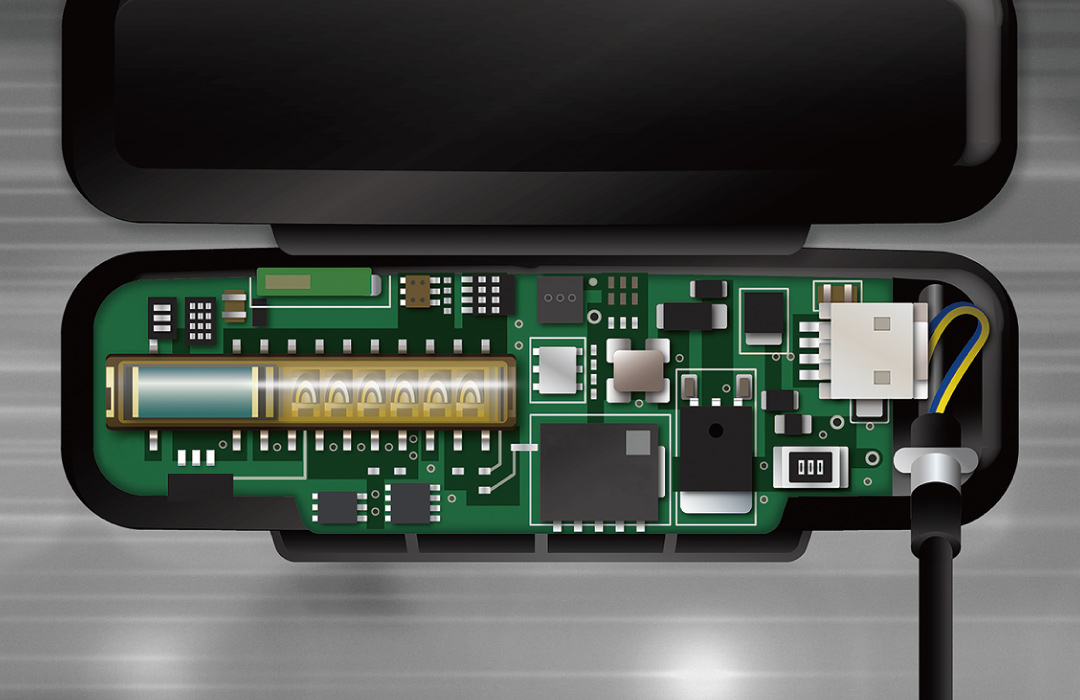

Sensor Lens

- LED light source

- Infrared light

- Optical connector

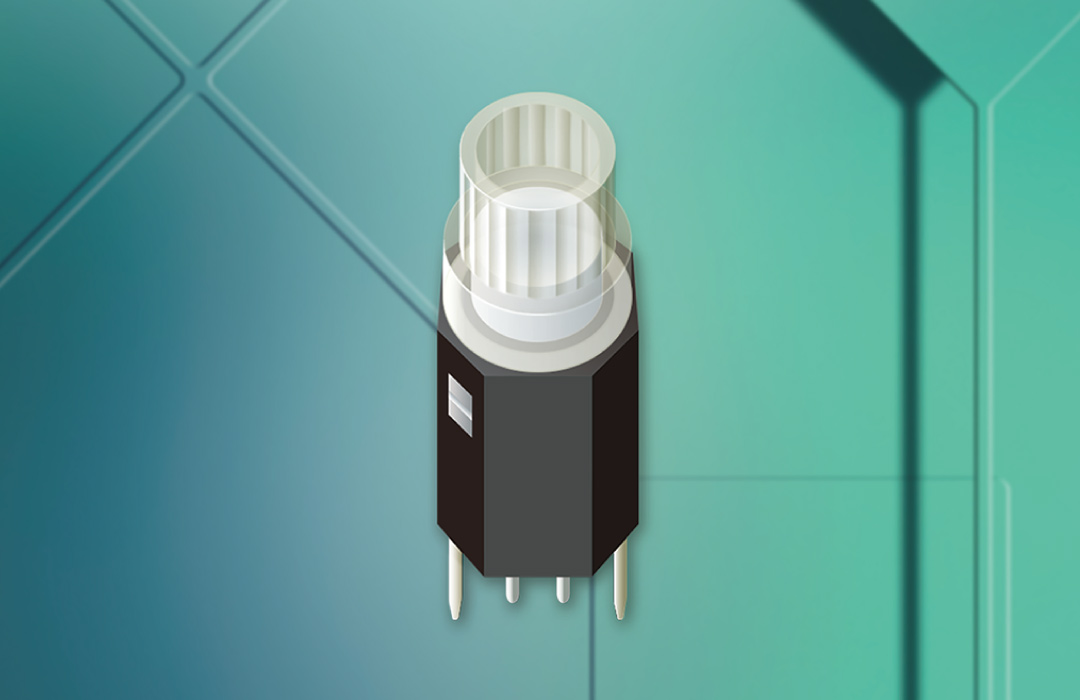

Switch cover

- Illuminated switch

- Diffuser

Characteristics

- Heat resisitance : glass transition temperature(Tg) of maximum 265°C

- Transparency : total light transmittance which approaches to 90%

- Density : 1.1~1.2g/cm3, the lowest among amorphous super engineering plastics

- Mechanical property : It has a yield point and excellent toughness

- Enhancing technical support system : CAE resin flow analysis, use of vacuum degassing equipment with quantitative feeder

Properties

| Item | Test Condition | Test Method | Unit | T-200 | T-240AF | |

|---|---|---|---|---|---|---|

| Mechanical properties |

Tensile strength | Yeild | ISO 527-1, -2 | MPa | 80 | 77 |

| Break | - | - | ||||

| Tensile modulus | - | MPa | 2300 | 2200 | ||

| Tensile strain | Yeild | % | 10 | 10 | ||

| Break | 15 | 18 | ||||

| Flexural strength | — | ISO 178 | MPa | 112 | 106 | |

| Flexural modulus | — | MPa | 2300 | 2200 | ||

| Charpy impact strength | Unnotched | ISO 179-1eU | kJ/m² | - | - | |

| Notched | ISO 179-1eA | 6 | 11 | |||

| Rockwell hardness | R | ISO 2039 | - | - | - | |

| Thermal properties |

Coefficient of linear thermal expansion |

Parallel | ISO 11359-2 | 10-4/°C | 0.7 | 0.7 |

| Transverse | 0.7 | 0.7 | ||||

| Deflection temperature under load |

1.8MPa | ISO 75-1, -2 | °C | 250 | 210 | |

| 0.45MPa | 258 | 216 | ||||

| Vicat softening temperature |

50N, 120°C/h | ISO 306 | °C | 261 | 217 | |

| Glass transition temperature |

- | ISO 3146 | °C | 265 | 218 | |

| Electrical properties |

Volume resistivity | - | IEC 60093 | Ω·m | 1014 | 1014 |

| Electrical strength | 1mmt | IEC 60243-1 | kV/mm | - | - | |

| Relative permittivity | 106Hz | IEC 60250 | - | 2.8 | 3.1 | |

| Dissipation factor | 106Hz | IEC 60250 | - | 0.02 | 0.02 | |

| Comparative tracking index |

- | IEC 60112 | - | - | - | |

| Other properties |

Density | - | ISO 1183 | g/cm³ | 1.12 | 1.17 |

| Water absorption | 23°C immersion 24h |

ISO 62 | % | 0.35 | 0.27 | |

| Mold shrinkage | Parallel | Unitika method 3mmt |

% | 0.6~0.8 | 0.6~0.8 | |

| Transverse | 0.6~0.8 | 0.6~0.8 | ||||

| Luminous transmittance |

3mmt | ASTM D-1003 | % | 87 | 88 | |

| Liquidity | Melt flow rate | Load 2.16kg |

ISO 1133 | °C | 380 | 380 |

| g/10min | 2.7 | 13.9 | ||||

| Flame retardance |

- | - | UL94 | - | HB(1.5mmt) | - |

(July, 2020)