U-Imide® Varnish Type BP

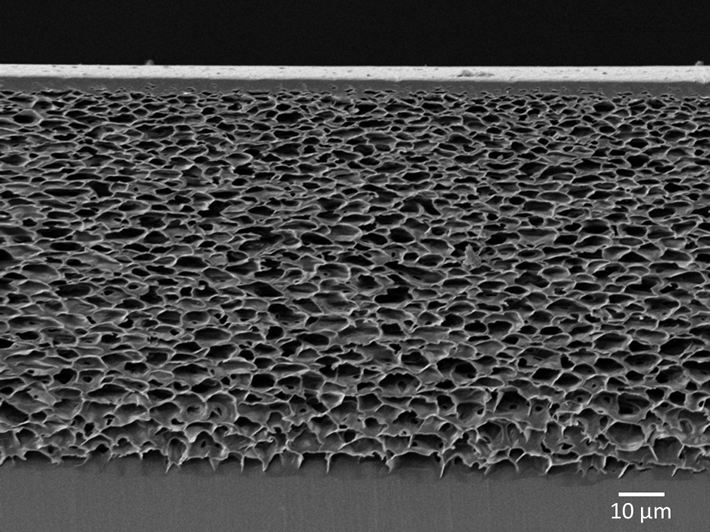

Through our unique technology, we have developed a polyimide precursor (polyamic acid) solution that facilitates the formation of porous polyimide layers. This product allows porous polyimide layers to be formed using the same equipment and process as used to form standard polyimide coatings.

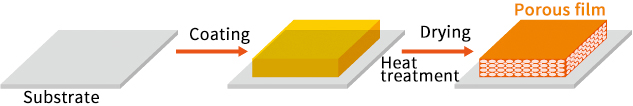

A simple process involving only coating, drying, and heat treatment

Features

Simple process

Porous polyimide coatings can be produced using typical coating, drying, and heat treatment equipment.

Low environmental impact

No poor-solvent immersion is required to form porous layers, and no liquid waste is generated.

Suitable for various shapes

With its ease of application, U-Imide Varnish enables porous polyimide coatings to be formed on substrates of various shapes, including plates, films, and tubes. Varnish properties (such as viscosity and concentration,) and coating properties (such as strength and porosity) can be adjusted to meet customer requirements.

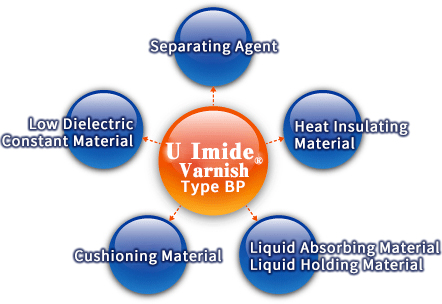

Typical applications

| Item | Unit | Porous Polyimide (BP varnish coating) |

Non-Porous Polyimide (reference) |

Test Method |

|---|---|---|---|---|

| Thickness | µm | 50-300 | 30 | |

| Porosity | % | 70 | 0 | |

| Elastic modulus | MPa | 600 | 3000 | ASTM D882 compliant |

| Thermal contraction coefficient [200°C] | % | <0.1 | 0.2 | JIS K 7133 compliant |

| Thermal expansion coefficient [50℃ to 200℃] | ppm/℃ | 40 | 27 | JIS K 7197 compliant |

| Thermal conductivity | W/mK | 0.04 | 0.16 | JIS R 1611 compliant |

| Dielectric constant [1 MHz] | ー | 1.4 | 3.3 | JIS K 6911 compliant |

| Dissipation factor [1 MHz] | ー | 0.004 | 0.009 |