U-Imide® Varnish

U-Imide Varnish is a polyimide precursor (polyamic acid) solution developed by Unitika.

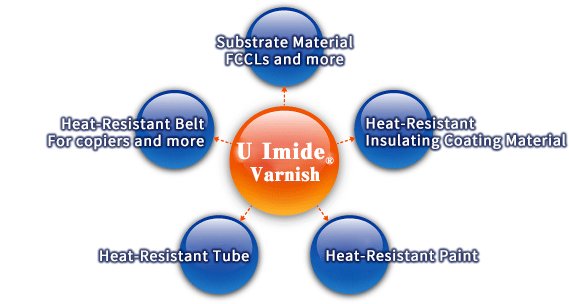

Applying U-Imide Varnish to a substrate and heat-treating it causes an imidization reaction, forming a polyimide coating with the highest level of heat resistance among polymers. Thanks to its excellent coating properties (heat resistance, chemical resistance, electrical properties, and mechanical properties) and ease of application and molding, U-Imide Varnish is used in a broad range of heat-resistant applications.

Features

High mechanical properties

In addition to causing an imidization reaction, post-application heat treatment promotes polymerization, thus forming a polyimide coating with excellent mechanical properties.

From standard to custom products

In addition to standard products, we also produce custom products with coating properties (such as strength, elongation, and color tone) and varnish properties (such as viscosity, concentration, and solvent) to meet customer needs. We can also produce varnishes containing no amide solvents (e.g., NMP, DMAc) and filler-dispersed varnishes.

Typical applications

| High Heat Resistance, High Elastic Modulus, High Strength |

High Heat Resistance, Low Elastic Modulus |

High Elongation | Test Method | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Brand | AR | AH | BH | C | CR | CH | |||

| Varnish properties | Viscosity | Pa·s | 5 | 100 | 2 | 3 | 5 | 100 | (30℃) |

| Concentration | wt% | 18 | 18 | 26 | 36 | 18 | 18 | ー | |

| Solvent | NMP | NMP | DMAc | DMAc | NMP | NMP | ー | ||

| Coating properties (reference values) |

Tensile modulus | GPa | 9.5 | 9.5 | 2.8 | 3.7 | 3.8 | 3.8 | ASTM D882 |

| Tensile strength | MPa | 375 | 410 | 135 | 175 | 195 | 205 | ||

| Tensile elongation | % | 25 | 30 | 70 | 80 | 90 | 95 | ||

| Glass-transition temperature | ℃ | >400 | >400 | >400 | 285 | 285 | 285 | DSC method | |