Types and general physical properties

There are two basic types of Arrowbase: polyethylene type (S Series) and polypropylene type (D Series). Please feel free to contact us if you require customization. Our technical staff will promptly improve the adhesiveness or other properties to solve your challenge.

General properties of Arrowbase (aqueous dispersion of modified polyolefin resin)

| Aqueous dispersion | S Series (Polyethylene type) |

D Series (Polypropylene) |

||||

|---|---|---|---|---|---|---|

| Main type | SB-1200 | SE-1200 | SD-1200 | DA-1010 | DB-4010 | |

| Resin | Melting point (°C) | 80 | 95 | 105 | 75 | 155 |

| Molecular weight (relative) | Middle | High | High | High | High | |

| Liquid characteristics | Appearance | Opaque white | Opaque white | Opaque white | Opaque white | Yellow, transparent |

| Solid content (wt%) | 25 | 20 | 20 | 25 | 25 | |

| Isopropanol content* (wt%) |

20 | 20 | 20 | < 1 | <1 | |

| pH | 9~11 | 9~11 | 9~11 | 9~12 | 9~12 | |

| Viscosity (mPa·s/25°C) | 50~300 | 50~500 | 30~300 | 1~100 | 1~100 | |

| Stability | > 1 year | > 1 year | > 1 year | > 1 year | > 1 year | |

*: Can be reduced to about 1 wt%.

(Updated on February 14, 2018)

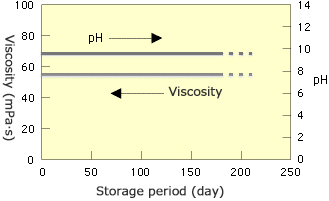

Storage stability

There is almost no change in the pH and viscosity when stored for 6 months at room temperature.

Coating conditions

Arrowbase coatings can be applied to substrates using known coating methods, such as gravure coating, wire-bar coating, lip coating, and spray coating, according to the viscosity. The appropriate amount of coating solution to apply at one time is approx. 5 to 20 g/m2. After the coating solution is applied, it should usually be heated and dried at 100°C to 150°C for about 30 seconds to form a coating, although a coating can also be formed by letting the solution dry at room temperature.