Main uses

With its excellent chemical resistance, good adhesion to a wide range of substrates, and heat sealability, Arrowbase can be used as a laminate adhesive, primer, anchoring agent, surface modifier, ink binder, and more.

1. Heat sealant

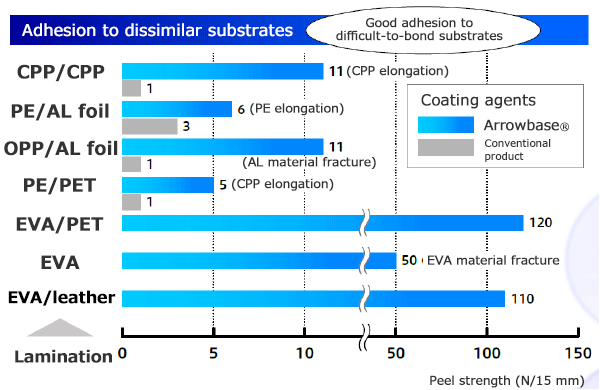

Arrowbase coatings have heat sealability—a property of polyolefin resin. As an example, the figure below shows the adhesion of Arrowbase to various materials by heat sealing. In particular, Arrowbase has excellent adhesion to olefin substrates such as PE, PP, and EVA. Additionally, Arrowbase has good adhesion to metallic materials, such as aluminum foil, and is suitable for bonding dissimilar materials together, including those with different polarities.

Furthermore, we offer types with improved adhesion to a wide variety of materials, such as PET, nylon, and urethane.

[Polyolefin Resin Water-Based Heat Sealant]

(PDF 0.9 MB)

Water-Based Coating Agent for Paper Materials]

(PDF 2.0 MB)

2. Anchoring agent for extrusion lamination

Applying Arrowbase to substrates and drying it allows polyethylene (PE) and polypropylene (PP) resins to be extrusion-laminated. For example, the adhesive strength is 5 N/15 mm or more when Arrowbase is applied to aluminum foil and dried so that the coating thickness is 0.5 µm and then PE (30 µm) is extrusion-laminated at 300°C or higher. In addition, the adhesive layer exhibits good resistance to various components. Recently, we have also developed a type that enables PP to be extrusion-laminated.

[Adhesive and Primer for PP]

(PDF 1.0 MB)

3. Highly adhesive coating (primer) for various films

Arrowbase adheres well to the various substrates described above. There are many examples where Arrowbase has been successfully applied to PET and olefin films. In addition, because Arrowbase coatings are colorless and transparent at a thickness of about 1 µm, they do not impair the haze, total light transmittance, or other optical properties of substrates.

[Water-Based Coating Agent for Forming a Highly Adhesive Layer]

(PDF 1.2 MB)

4. Binder for water-based ink

Inks and paints can be made by mixing pigments or dyes with Arrowbase. For example, it is possible to make an ink with good adhesion to olefin substrates.

5. Sealant for insert molding between metal and resin (special type)

By making full use of olefin resin dispersion technology and resin modification technology, we have developed a sealant for insert molding between metal and resin. This sealant is suitable for a wide variety of metals (e.g., stainless steel, aluminum, copper, various platings) and resins (e.g., ABS, PPS, PBT, PP). For example, when this sealant was applied to a 10-mm diameter aluminum rod and dried, and then polyphenylene sulfide (PPS) was insert-molded, the sealing prevented air from leaking even at a high pressure of 550 kPa. In addition, the sealant maintained good sealing after a heat shock test (1000 cycles between -30°C and 140°C).

Notes on use

Note 1

Arrowbase has excellent long-term storage stability at room temperature. However, leaving it exposed to air for extended periods of time can cause "skinning" or form aggregates. To prevent these problems, keep it in a sealed container after opening and use it as soon as possible.

Note 2

Arrowbase is stable as a liquid dispersion under basic conditions, and can coagulate when mixed with acidic substances.

Note 3

Although Arrowbase is an aqueous dispersion, some Arrowbase products containing solvents are classified as hazardous materials. Avoid open flames when using those products.

Note 4

Avoid direct contact with the skin. In case of contact with the skin, wash thoroughly with water.

Note 5

Consult the appropriate Safety Data Sheet (SDS) for more details.