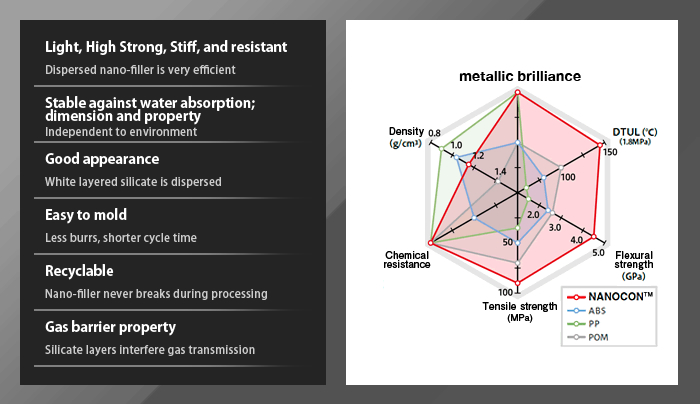

NANOCON has achieved high heat resistance, dimensional accuracy and a good appearance compared with normal polyamide 6. In addition to the chemical resistance with the original polyamide 6 resin, it also has weather and light resistance due to our original prescription. Because of its excellent strength and rigidity which is the greatest feature derived from Unitika's independent filler compounding technology.

NANOCON is also applicable to load-bearing parts, such as door handles.

NANOCON™

UNITIKA make a proposal to reduce costs of metallic colored parts by NANOCON compounds with metallic appearance. "NANOCON" is a high-gloss material that features metallic brilliance, rigidity, heat resistance, and chemical resistance.

Color Variation

The principle of the metallic brilliance

As each silicate layer has almost the same size as a polyamide 6 molecule chain itself, nanocomposite molding items have an excellent surface appearance compared with the conventional reinforced materials. Metallic pigment in NANOCON shine brilliantly because the synthetic layered silicate has fine white appearance compared with natural layered silicate an NANOCON itself is uncolored.

The characteristic of NANOCON

Nanocomposit polyamide 6 "NANOCON" is a reinforced material based on the polyamide 6 with numerous ultra-fine inorganic fillers. NANOCON is a novel composite material which has completely different properties from conventional composite materials reinforced with "micron-sized"fillers, such as glass fiber and talc.

Applications

Automotive parts [Case, Cover, Door-handle]

![Automotive parts [Case, Cover, Door-handle]](img/img-use01.jpg)

Other parts

"NANOCON" metallic resin is taking advantage of the high design property, it can widely applied as familiar products other than automotive.

Standard Properties Table

| Grade name | M1030DH | ||||

|---|---|---|---|---|---|

| Color | Silver metallic | ||||

| Properties | Test (ISO) |

Units | Dry-as-molded | 2.8% water absorption | |

| Tensile strength at break | 527-1, -2 | MPa | 95 | 65 | |

| Tensile strain at break | % | 3 | 4 | ||

| Flexural strength | 178 | MPa | 155 | 70 | |

| Flexural modulus | GPa | 4.5 | 2.5 | ||

| Charpy impact strength | 179-1eA | kJ/m² | 4 | 7 | |

| DTUL | 1.82MPa | 75-1, -2 | °C | 140 | |

| 0.45MPa | 190 | ||||

| Mold shrinkage (Thickness:3.0mm) |

MD | Unitika method | % | 1.1 | |

| TD | 1.2 | ||||

| Flammability | UL94 | — | HB equivalent | ||

| Density | 1183 | — | 1.15 | ||

| Water absorption (23°C/50%R.H.) |

— | % | 2.8 | ||

| Light resistance*1 | Unitika method | — | ΔE<3 | ||

*1 : Test condition;Xenon,BPT=89°C,No rain,300MJ/m²