Golf Courses

Needle Punched MARIX is a civil engineering material for golf courses that takes advantage of the features of polyester Spunbond nonwoven fabric. With unique water permeability, the fabric can drain water in both vertical and Horizontal directions. Its superior drainage is particularly useful for bunkers; no elevation of the ground surface occurs. The material is very strong and highly durable. It is used in greens, bunkers, and fairways in over 400 golf courses nationwide.

Benefits

- Drainage effect

Made of Spunbond nonwoven fabric, Needle Punched MARIX can drain water in both vertical and Horizontal directions. - Filter effect

Filaments tangled into felt fabric provides a filter effect equivalent to or greater than sand. - Reinforcement effect

Needle Punched MARIX prevents greens, tee grounds, and fairways from sinking unevenly and makes the ground stable. - Separation effect

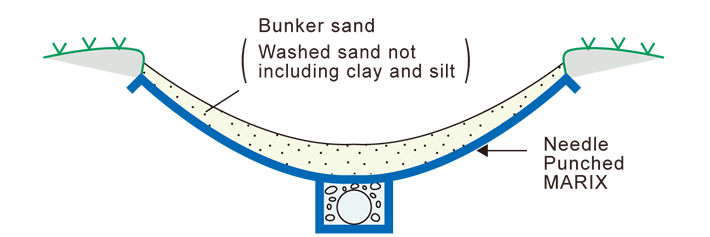

In a bunker, Needle Punched MARIX separates the soil of the base ground from sand and prevents their mixing, keeping the sand looking clean.

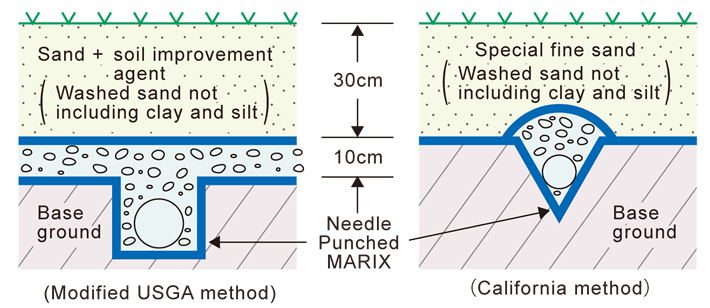

Green

Bunker

Main applications and applicable Item No.

| Location | Construction method | AN120 | AN160 | AN200 | AN300 | AP110 |

|---|---|---|---|---|---|---|

| Golf courses | Soil layer separation and horizontal drainage. | ○ | ○ | ○ | ○ | ○ |

Properties [catalog values]

| Item No. | Specification | Weight (g/m²) |

Thickness (1) (mm) |

Thickness (2) (mm) |

Tensile strength (N/5cm) |

Elongation (%) |

Tearing strength (N) |

Water permeability coefficient (cm/sec) |

Burst Strength (N) |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Color | Width (m) |

Roll length (m) |

*MD | *CD | *MD | *CD | *MD | *CD | Vertical direction |

Horizontal direction |

|||||

| AN120 W | White | 2.1 | 100 | 120 | 1.2 | 1.0 | 390 | 235 | 55 | 60 | 65 | 105 | 1×10-1 | 5×10-1 | – |

| AN160 B | Black | 2.1 | 100 | 160 | 1.5 | 1.3 | 490 | 340 | 55 | 60 | 155 | 175 | – | ||

| AN200 B | Black | 2.1 | 100 | 200 | 2.1 | 1.6 | 630 | 500 | 60 | 60 | 195 | 245 | – | ||

| AN300 B | Black | 2.1/4.2 | 50 | 300 | 3.0 | 2.4 | 1170 | 980 | 60 | 60 | 245 | 290 | – | ||

| AP110 B | Black | 2.1 | 100 | 110 | 1.0 | 1.0 | 290 | 245 | 35 | 40 | 125 | 125 | – | ||

* MD(machine direction)/*CD(cross direction)

* The measurement method shall comply with the following.

Tensile strength/tensile elongation: JIS L-1908

Tearing strength: JIS L-1096 (single tongue method)

Burst Strength: ASTM D 4833

Water permeability coefficient: JIS A-1218

Thickness (1): JIS L-1096 (pressure 7g/cm²)

Thickness (2): JIS L-1908 (pressure 20g/cm²)

The AN types are hydrophilically treated.