- Polymers

- Leveraging our track record and innovation in our core business that is polymers, we are bringing our original high value-added line of products to the global market.

The polymers business is largely divided into two areas: films and plastics.

As a result of realizing numerous world firsts and expanding the possibilities of materials, it has become the core business upon which Unitika rests today.

While giving priority to developing environmentally friendly materials, we pursue the kind of performance and quality only Unitika can deliver as we strive to bring more lines of high value-added products to the global market.

Films

The world’s leading nylon films for food packaging.

Unitika’s film lineup includes top share nylon films, developed based on the world’s first simultaneous biaxially orientation method and polyester films, designed using unique technologies to suit distinctive applications. Unitika has developed and been producing a range of cutting-edge products, including gas barrier films for packaging materials and high heat-resistant films for electronic applications by strengthening collaboration among the marketing team, R&D group, and production division.

As the global leading Nylon film manufacturer supplying products from the factories in Japan and Indonesia, Unitika is aiming to further expand their footprints in European and North American markets as well as Asian market by focusing on the development of specialty films.

-

EMBLEM

A world first, simultaneous biaxially oriented nylon film developed by Unitika. “EMBLEM” boasts superior strength, flexibility and rupture resistance and is the world’s leading brand of food packaging. -

EMBLEM-HG

High gas barrier Nylon films designed specifically for retorting and boiling applications. “EMBLEM HG” is enough robust to retain the barrier function even under tough physical stress. -

EMBLEM-NC

Nylon films with the linear tearing function. Gas barrier grades are also available. -

EMBLET-PC

Linear tearing PET films that makes package opening easier.

Gas barrier function can be added by the vapor deposition treatment. -

Co-extrusion multi-layer BOPA (Packaging application)

Tri-layer co-extruded polyamide films, where a barrier resin is sandwiched in the middle. Because of its environmentally friendly nature as well, “EMBLON” has been chosen in a variety of applications both for food and non-food. -

UNIPEEL

Unique silicon free PET release films developed with Unitika’s proprietary technologies. The applications as release film are versatile including the electronic field because “UNIPEEL” eliminated the concern about silicon contamination during the production process. -

UNIAMIDE

Biaxially oriented high heat-resistant polyamide films. Unitika’s experience and technical expertise in film processing enabled this resin to be converted into oriented films. Electric and electronic uses are the typical applications that can take full advantage of “UNIAMIDE”’s characteristics. -

Film processing

U.C.S Co., Ltd. is involved in the process of slitting film products to a width and length to meet customer’s requirements. U.C.S has the technological capabilities to promptly meet even the most urgent customer orders.

- Related link

- Films Division UNITIKA FILM-Technical information

Plastics

Unitika is currently promoting a global niche strategy in the field of plastics. It currently has its sights set on the global market for engineering plastics and is focusing on the Asian market for liquid, non-molded materials. Based on our highly unique “U-Polymer”, Unitika is seeking further collaboration with its partner companies to reinforce its development, production and sales framework in the area of engineering plastics as it aims to expand from applications in the rapidly changing automotive industry into energy and aerospace applications. A key priority for us will be to keep our finger on the pulse of the market and deliver necessary products that will form the “standard”.

-

Nylon 6 resin

Nylon 6 and Nylon 66 resin provide superior molding properties and strength and are used in a diverse range of applications, such as electronic parts, electrical parts, automotive parts, industrial and construction materials and household goods.

Nylon 66 resin -

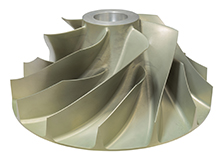

NANOCON

“Nanocon” is a composite material boasting superior hardness, heat resistance and moldability. Potential applications, such as engine covers etc. for this product are growing. -

U-POLYMER

Unitika was the first in the world to develop industrialized polyarylate resin. It is used in a range of applications, including precision equipment, cars, machinery, medicine, food products and everyday goods etc. -

XecoT

“XecoT” is an aromatic polyamide resin made from biomass material which has overwhelming performance developed based on Unitika’s original polymerization and compound technology. -

ARROWBASE

“Arrowbase” is a groundbreaking, modified water-based polyolefin emulsion that does not contain surface acting agents. -

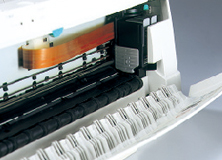

ELITEL

Flat cable adhered using “Elitel”. “Elitel” is used in a range of electronic equipment and products, including laptop computers and printers etc. -

Unilate

Unilate is a sheet product made from polyester-based resin. It supports the IT industry and is used for parts in electrical devices and in circuit boards for electronic equipment. -

Terramac (polylactic acid resin)

Terramac has been used in the production of mobile phone cases. Biomass materials are presently making a real impact in a variety of aspects in our day-to-day lives.

"N701iECO (NTT DoCoMo)" -

PET resin

Lightweight and boasting superior strength and moldability, “PET resin” is commonly found in containers used in everyday life, including cosmetic products etc. -

U-IMIDE

Aromatic polyimide boasting superior heat resistance compared to other polymers. U-IMIDE meets a range of customer needs in the form of a polyimide coating agent created harnessing our unique technologies. -

Encapsulation molding

Unitika has established encapsulation molding technologies where key components, such as electronic components, etc. are placed in a mold and encased with resin. This technology is being used to create the world’s smallest waterproof devices and now forms the industry standard in the field of photoelectric switches. -

Recycled resin

Terabo, a manufacturer of high-quality compounds, such as engineering plastics, also meets demand for the recycling of thermoplastic resins.

- Related link

- Plastics Division

Biomass-based material(Terramac)

“Terramac” is a biomass material made from the starch found in corn etc. It is currently attracting attention as an eco-material with no load on the global environment to replace oil-based plastics. Unitika is developing “Terramac” in a range of forms, including textiles, spunbond fabric and resins etc.

- Related link

- TERRAMAC