Super Engineering Plastic Film for FPC

Low Modulus

Heat Resistant Film

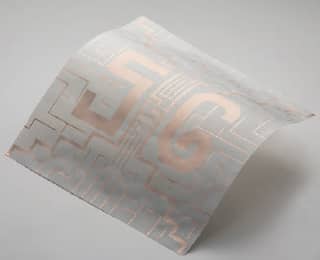

Expands the possibilities of high frequency flexible printed circuits (FPC).

This is a new type of polyamide film that achieves both low modulus and heat resistance, which was previously difficult to combine for films. It shows excellent adhesion with copper foil and this feature makes the lamination process easier. The film can be used in a wide range of applications where conventional low-elasticity films do not fit because of the low heat resistance.

Features

- ・Made from Unitika’s unique polyamide resin

- ・Low modulus and heat resistant functional film

- ・Excellent in electrical characteristics and bending resistance

- ・Excellent in adhesion and chemical resistance

Performance balance

Stress-Strain curve

Mechanical properties

| Items | Unit | Low Modulus Heat Resistant Film |

High elongation type |

|---|---|---|---|

| Thickness | μm | 50 | 100 |

| Tensile strength | MPa | 110 | 60 |

| Tensile elongation | % | 130 | 280 |

| Tensile elastic modulus | GPa | 1.9 | 1.3 |

| Moisture absorption*1 | % | 0.6 | 0.6 |

| Peel strength*2 | N/mm | 0.5 | - |

*1 20℃ 65%RH × 24hr

*2 Hot press Lamination with low-roughness copper foil

Thermal properties

| Reflow soldering compatibility | 260℃ × 1 min | Good | |

|---|---|---|---|

| Heat shrinkage | % | 150℃ × 15 min | 0.3 |

| 200℃ × 15 min | 0.9 | ||

Internal method ’Visual observation of the film after heat treatment’

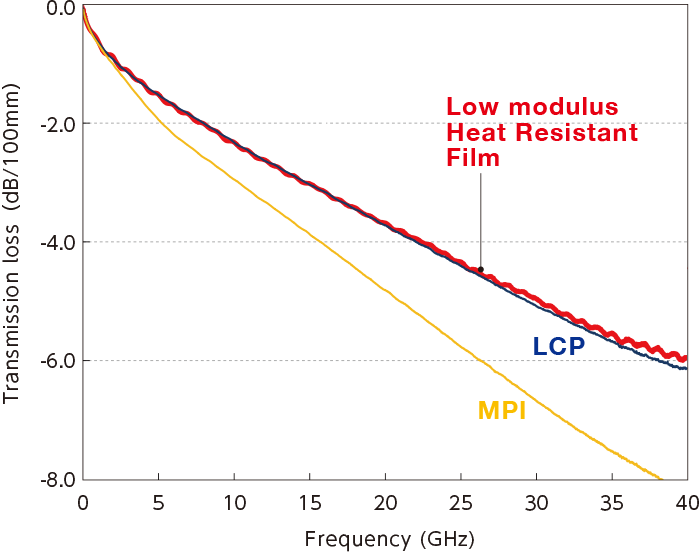

Dielectric characteristics

| Items | Low modulus Heat Resistant Film | MPI | LCP |

|---|---|---|---|

| Dielectric constant | 2.7 | 3.7 | 3.3 |

| Dielectric dissipation factor | 0.005 | 0.005 | 0.002 |

Cavity perturbation method; 5.8 GHz, 23℃ 50%RH

Transmission loss

Applications

High frequency flexible printed circuit board

< FPC and related substrates >

- ・High speed antenna FPC

- ・Low modulus FPC

- ・Flexible flat cable

- ・High speed antenna FPC

- ・Flexible coverlay

< Others >

- ・Heat resistant tape

- ・Sealing film

- etc.

Catalog

PDF Download (1.1MB)< March 23, 2022 >