Organic Solvent Resistant Hollow Fiber Membrane Modules.

Microfiltration and

Ultrafiltration Membrane Modules

Organic solvent compatible new separation membrane realizes process innovation.

By Unitika's proprietary polymer processing technology, we have developed the liquid separation membranes with polyamide that can be used in organic solvent systems. This feature contributes to energy saving and cost reduction in the processes such as concentration of target substances, removal of impurities and regeneration of waste solvents.

Features

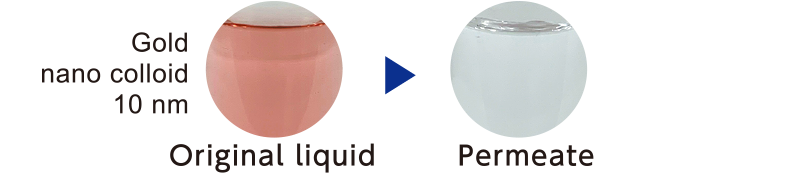

- ・Capable of separating nano-particles and dissolved polymer components from various organic solvents!

- ・Non-heating process enables the separation of heat-sensitive components!

- ・Contributes to energy, resource, and cost saving as an alternative to distillation!

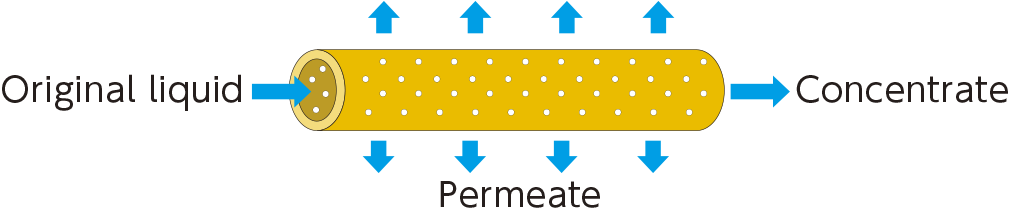

Separation principle of hollow fiber membranes

Examples of WINSEP™ Applications:

WINSEP™ MF

- ・Concentration, separation, and classification of fine particles in manufacturing processes

- ・Emulsion separation

- ・Removal of foreign substances in chemicals for semiconductor manufacturing processes

WINSEP™ UF/NF

- ・Concentration, separation, and recovery of products in organic synthesis or polymer manufacturing processes

- ・Concentration and separation of natural components without heating

- ・Removal of binder resin in waste liquid, reuse of solvents

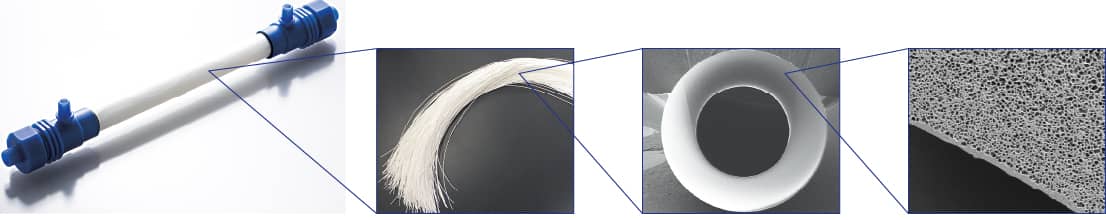

Inside of the membrane module

Organic solvents usable with the hollow-fiber membrane module*

- ・Alcohols (Methanol, IPA etc.)

- ・Hydrocarbons (Hexane, Toluene etc.)

- ・Ketones (Acetone, Cyclohexanone etc.)

- ・Esters (Ethyl acetate, PGMEA etc.)

- ・Ethers (THF, PGME etc.)

- ・Others (Piridine, NMP, DMAc, DMF, DMSO etc.)

* Please contact us for the solvent compatibility not listed above.

Separation membrane lineup

| Types | Pore size |

|---|---|

| MF | Mean pore size 2 5 10 40 100 nm |

| UF | Mean molecular weight cut off 3,000 30,000 120,000 Da |

| NF | Mean molecular weight cut off < 1,000 Da* |

*: The separation size of NF membranes varies depending on the properties of the solvent and solute

Examples of WINSEP™ separation:

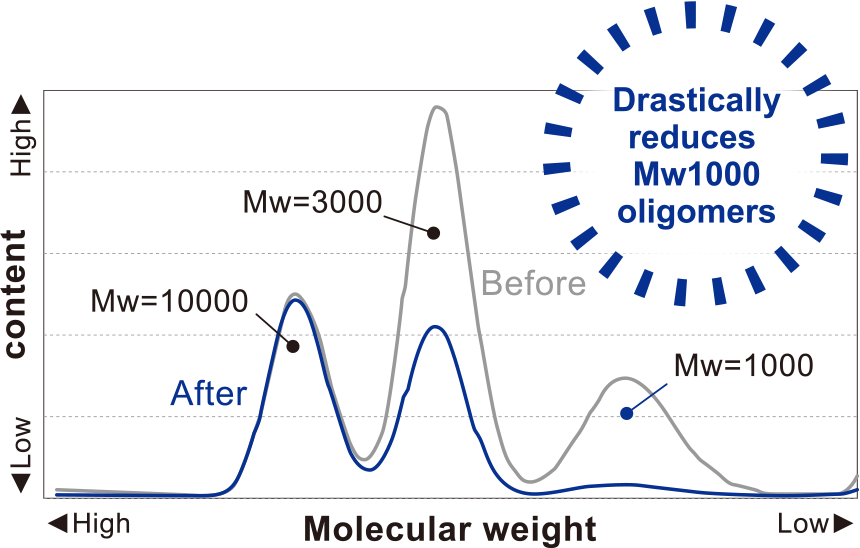

Polymer/Natural Product Purification:

Solves issues such as:

- ・Cannot be purified by conventional poor solvent methods

- ・Cannot be distilled due to heat sensitivity

<Example of polystyrene mixed solution separation:>

Membrane: WINSEP™ UF

Solvent: N-Methyl-2-pyrrolidone

Polymer: Polystyrene (mixture of molecular weights 10,000/3,000/1,000)

Measurement: Gel permeation chromatography (GPC)

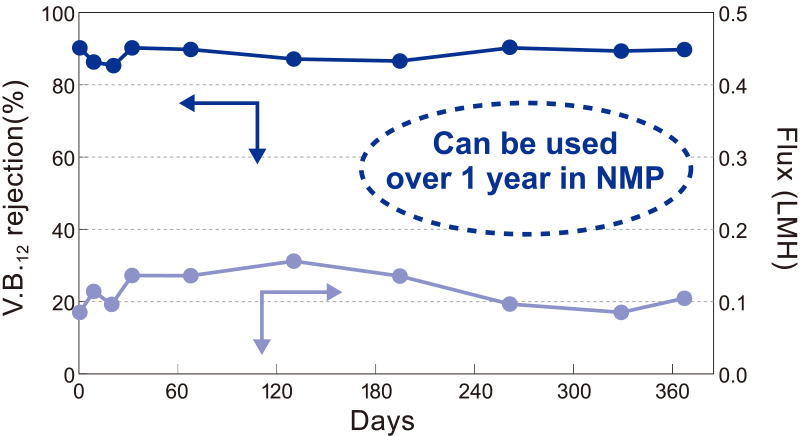

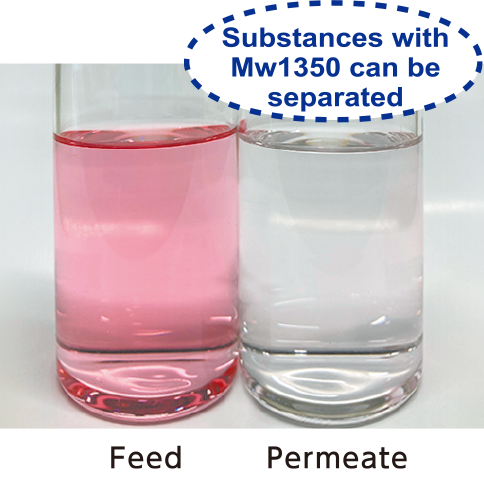

<Example of Vitamin B12 separation:>

Membrane: WINSEP™ NF Solvent: N-Methyl-2-pyrrolidone Solute: Vitamin B12 (MW=1,350) Operating pressure: 2MPa

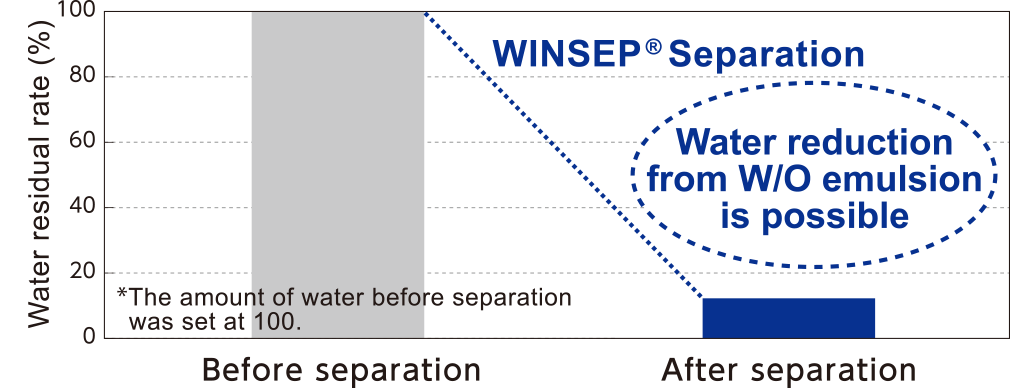

w/o emulsion separation:

Solves issues such as:

- ・Conventional purification methods (distillation, coalescers, etc.) are not applicable or insufficient

- ・Cannot be distilled due to heat sensitivity

- ・Membranes for o/w emulsion separation deteriorate

<Example of w/o emulsion separation:>

Membrane: WINSEP™ MF-2nm

Dispersing medium: Isoparaffin-based hydrocarbon (90%)

Dispersed substance: Water (10%)

Membrane: WINSEP™ MF-2nm

Surfactant (HLB7): 1% added

Dispersing medium: Isoparaffin-based hydrocarbon (90%)

Dispersed substance: Water (10%)

Catalog

PDF Download (1.4MB)< March 23, 2022 >