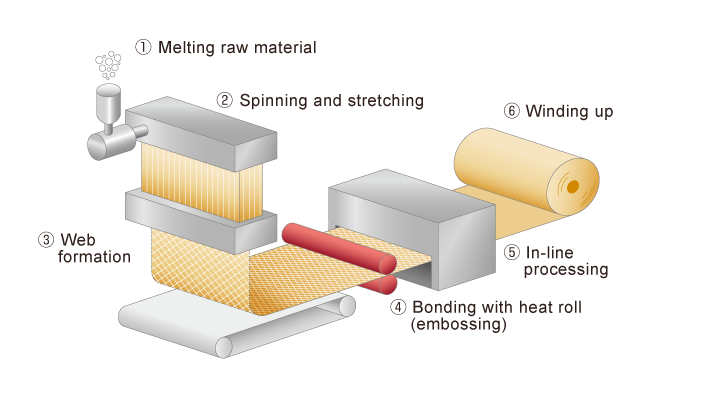

Spunbond method

- Melt polymer chips(raw material).

- Form filaments by spinning the molten polymer and stretching the molten filaments.

- Separate and spread fiber bundles of many filaments, and lay down the fibers on a net to form a web.

- Bind the fibers in the form of a sheet through thermal bonding and perform embossing.

- Perform special in-line processing such as calendar processing.

- Wind up the sheet.

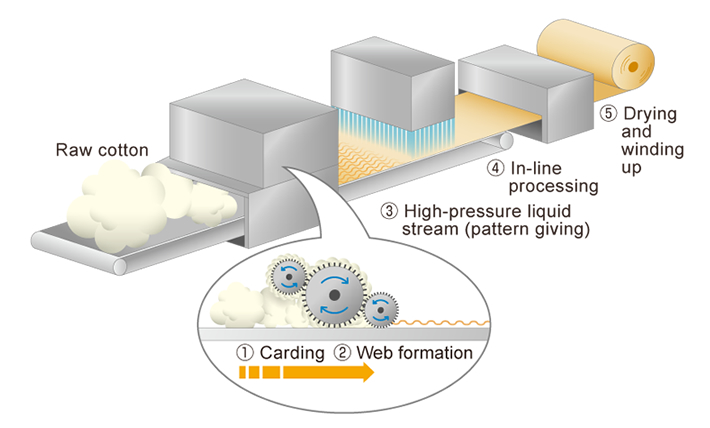

Spunlace (hydroentangling) method

- Organize fibers by carding.

- Form a drylaid web.

- Staple fibers are entangled together by high-pressure liquid stream, and form a nonwoven fabric.

- Perform special in-line processing.

- Dry and wind up the sheet.