Industrial Waste Final Disposal Site

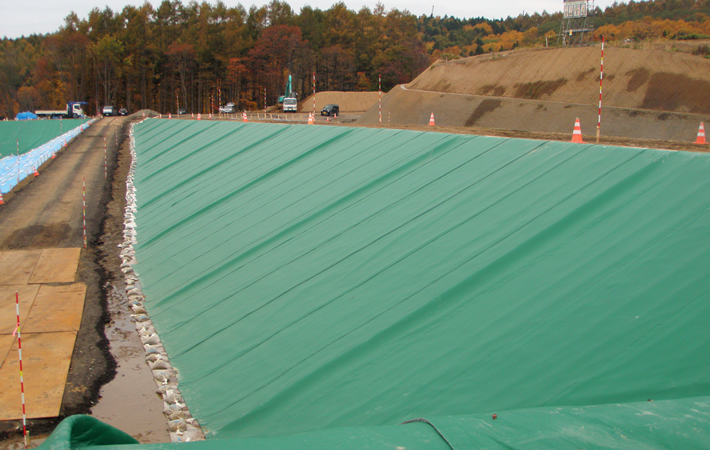

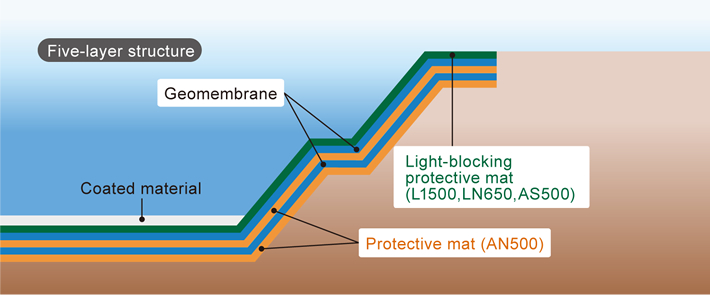

These are light-blocking protective mats we have developed for use in Industrial Waste Final Disposal Site by leveraging the features of Needle Punched MARIX. The mats are superior not only in strength and weather resistance but in elongation, cushioning property, and light-blocking performance as well. They are used as protective buffering materials that can protect against even deformed protrusions.

LN650 and L1500 are three-layer mats that use a polyethylene laminated layer on the top surface and ELEVES (polyethylene sheath and polyester core) on the rear surface, which can be bonded together using a self-propelled hot wind pressure welding machine. Their bonding performance is excellent.

Standard properties

| Item No. | Weight (g/m²) |

Tensile strength (N/cm) |

Burst Strength (N) |

Weather resistance (N (*1)) |

Shading rate (%) |

Safety level |

|---|---|---|---|---|---|---|

| LN650/PAL | 650 | 300 or more | 1000 or more | 800 or more | 100 | Below the limits specified in environmental quality standards for groundwater and water quality |

| L1500/PNL | 1500 | 100 or more | 1500 or more | 1000 or more | 100 | |

| AS500/GRE | 500 | 300 or more | 900 or more | 750 or more | 100 | |

| AN500/BKE | 500 | 300 or more | 900 or more | 600 or more | 99 or more | |

| Measurement method |

JIS-L-1908 | JIS-L-1908 | ASTM D 4833 | ASTM D 4833 | JIS-L-1055 | – |

(1*) Burst Strength after the WS-type accelerated exposure test (JIS-A-1415, 1000 hr)

Specification

| Item No. | Specification | Water permeability |

Flame resistance |

Self-propelled hot wind pressure welding machine |

Structure | ||||

|---|---|---|---|---|---|---|---|---|---|

| Color | Width (m) |

Roll length (m) |

Top surface layer |

Middle layer |

Rear surface layer |

||||

| LN650/PAL | Green | 2.1 | 50 | Not supported | Supported | Usable | Polyethylene | PET Spunbond nonwoven |

ELEVES |

| L1500/PNL | Green | 2.1 | 30 | Not supported | Supported | Usable | Polyethylene | PET Staple nonwoven |

ELEVES |

| AS500/GRE | Green | 2.05 or 4.1 | 50 | Supported | Supported | Not usable | Acrylic resin | PET Spunbond nonwoven |

|

| AN500/BKE | Black | 2.1 or 4.2 | 50 | Supported | Not supported | Not usable | PET Spunbond nonwoven |

||

| Measurement method |

– | – | – | JIS-A-1218 | 45° air mix burner method | – | – | ||

Gas-Permeable/Waterproof Sheet (ELEVES as Capping Sheet) (CP600)

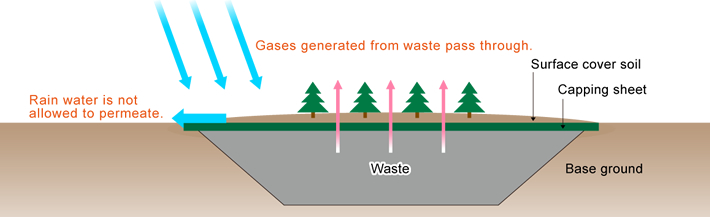

When a final repository site is closed, the use of the capping method is required that can prevent rain water from permeating the waste and ensure safe waste confinement in order to reduce the risk of seepage water contaminating the environment as well as the cost of seepage water disposal. We have developed a new type of capping sheet jointly with the Society for Research on Geosynthetics Technology. This capping sheet features a seepage control function that prevents rain water permeation and a gas permeability property that lets residue gases generated from waste pass through to the atmosphere while at the same time satisfying the physical performance requirements that need to be met during construction and use.

Made of ELEVES (polyester/polyethylene core-sheath structure), the capping sheet has superb thermal adhesiveness and is suitable for bonding by means of a self-propelled hot wind pressure welding machine. In addition, applying heat and pressure to edges makes bonded parts water repellent.

Standard properties

| Item No. | Mass (g/m²) |

Thickness (mm) |

Tensile strength (N/5cm) |

Elongation (%) |

Tearing strength (N) |

Burst Strength (N) |

Water resistance (kPa) |

Humidity permeability (g/m².24h) |

|||

|---|---|---|---|---|---|---|---|---|---|---|---|

| *MD | *CD | *MD | *CD | *MD | *CD | ||||||

| CP600 | 600 | 4.5 | 1200 | 925 | 60 | 60 | 185 | 220 | 600 | 220 | 3000 |

* MD(machine direction)/*CD(cross direction)

<Measurement method>

Mass/thickness/tensile strength/elongation: JIS L-1908

Tearing strength: JIS L-1096

Burst Strength: ASTM D 4833

Water resistance: High hydraulic method JIS L 1092

Humidity permeability: A-1 method JIS L 1099