ELEVES as Capping Sheet

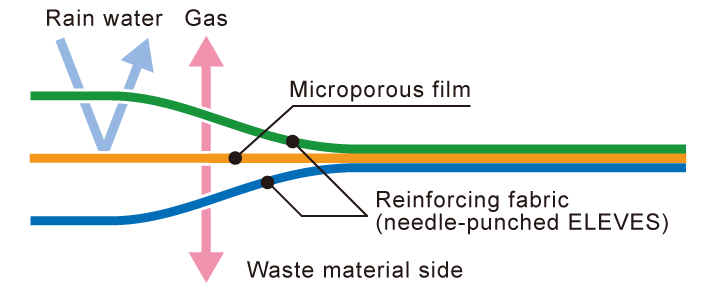

「ELEVES as capping sheet are three layer products; i.e. microporous films sandwiched between two ELEVES.

The use of ELEVES gives the sheet superb thermal adhesiveness, making it suitable for bonding by means of a self-propelled hot wind pressure welding machine. What's more, applying heat and pressure to edges prevents water seepage from bonded parts, which makes this product a high-quality Gas-Permeable/Waterproof Sheet. The ELEVES as capping sheets are used as covering sheets in temporary storage sites for decontamination waste materials in the disaster-damaged areas.

Standard properties

| Mass (g/m²) |

Tensile strength (N/5cm) |

Burst Strength |

Weather resistance (Burst Strength) |

Water resistance |

Humidity permeability (g/m².24h) |

Shading rate |

Safety level |

|||

|---|---|---|---|---|---|---|---|---|---|---|

| *MD | *CD | N | N | mmH2O | kPa | Per 24 hours | % | Elution property |

||

| Common specifications for decontamination and other types of work of the Ministry of the Environment |

*400 or more |

*925 or more |

*925 or more |

*500 or more |

*500 or more |

1000 or more |

– | 2500 or more |

*95 or more |

* Below the standard value |

| ELEVES as Capping Sheet CP600 |

600 or more |

1200 or more |

925 or more |

600 or more |

600 or more |

2000 or more |

220 or more |

3000 or more |

95 or more |

Below the standard value |

*Voluntary Standard value for protective mats specified by the Japan Water Seepage Control Engineer Association

*Voluntary Standard value for protective mats specified by the Japan Water Seepage Control Engineer Association

* MD(machine direction)/*CD(cross direction)

<Measurement method>

Mass/tensile strength: JIS L-1908

Burst Strength: ASTM D 4833

Weather resistance: JIS-A-1415; WS-type accelerated exposure test; Value of the Burst Strength test after 1000-hour exposure

Waterproofness: Low hydraulic method JIS L 1092 (mmH2O); High hydraulic method JIS L 1092 (kPa)

Humidity permeability: A-1 method JIS L 1099