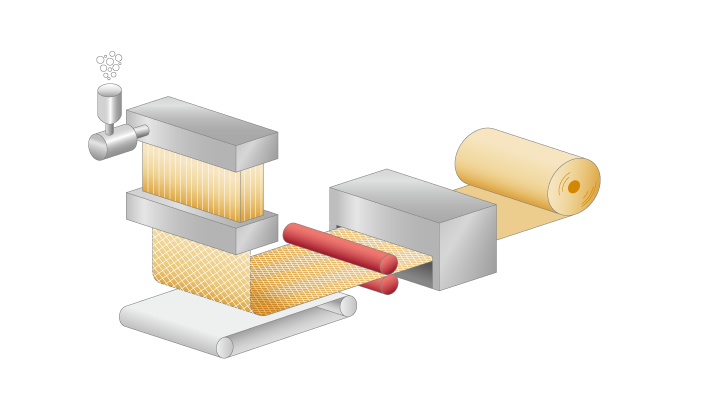

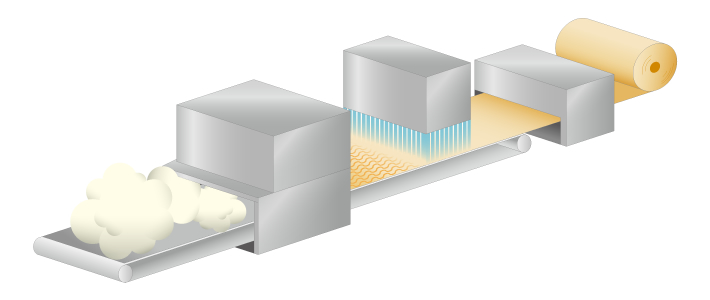

This method first melts resin tips, which are the raw material, into filaments. Then, after the filaments are accumulated on a net to form webs, those webs are bonded in the form of a sheet.

The major conventional method of manufacturing nonwoven fabric involves two processes: (1) processing resin into filaments such as staple fibers and (2) processing them into nonwoven fabric. With the spunbond method, by contrast, all the processes from filament spinning to nonwoven fabric formation are performed at once, thus enabling speedy production. Made from non-fragmented long filaments, spunbond nonwoven fabric is very strong and dimensionally stable and can be used in a variety of applications.

In addition to products made of polyester and polyester-polyethylene composite, we have been active in recent years in developing products that address increasingly challenging environmental issues, such as TERRAMAC, which is biodegradable plastic made from plant-derived polylactic acid, and Recycled Needle Punched MARIX made from recycled polyester.

View manufacturing process