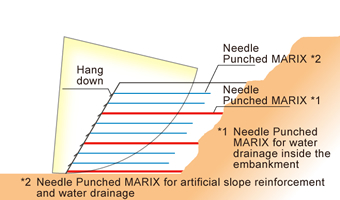

Embankment

The embankment reinforcement method using geotextile is making a huge change to embankment construction work. Amid this situation, Needle Punched MARIX, our state-of-the-art geotextile, is attracting attention from the civil engineering industry as an ideal reinforcement material. In the case of an embankment of viscous soil, where water is not drained easily, the strength of the embankment is greatly reduced by rain water or water seeping from the ground. An embankment of sandy soil, on the other hand, has a serious problem when it has a steep slope.

Needle Punched MARIX, which offers a synergy between drainage capability and tension-reinforcing capability, is effective for embankment construction work using viscous or sandy soil, earning a remarkable reputation as the geotextile of the 21st century.

Benefits

- Reinforcement effect

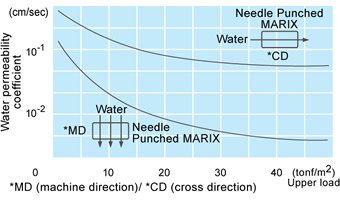

Since Needle Punched MARIX is flexible and has a large coefficient of soil friction, it allows integrated soil structures to be built. - Drainage effect

Made of Spunbond nonwoven fabric, Needle Punched MARIX can drain only water in both vertical and Horizontal directions.

Features

- Filter performance

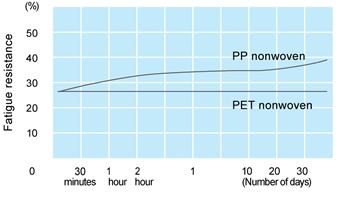

Randomly arranged numerous filaments provide a filter function. The fabric does not become clogged easily and serves as an excellent filter that drains only water. - Fatigue resistance

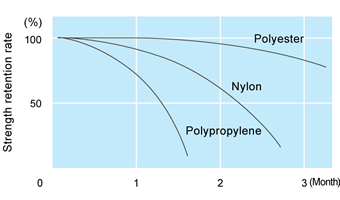

Needle Punched MARIX is made of polyester, which is insusceptible to property changes such as creeps that occur when material is left under a certain load for a long period of time. - Weather resistance

Polyester is more resistant to changes in weather, temperature, etc. than other materials. Its property does not almost change even in water or under the ground.

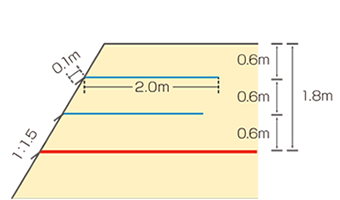

- Example of embankment

reinforcement design

Detail of example design

- Filter performance

- Fatigue resistance

- Weather resistance

Main applications and applicable Item No.

| Location | Construction method | AN160 | AN200 | AN300 | AN400 |

|---|---|---|---|---|---|

| Drained lands /landfills /developed lands |

Horizontal drain for embankment | ○ | ○ | ○ | |

| Roads/sidewalks | Embankment on soft grounds | ○ | ○ | ○ | ○ |

| Horizontal drain for embankment | ○ | ○ | ○ |

Properties [catalog values]

| Item No. | Specification | Weight (g/m²) |

Thickness (1) (mm) |

Thickness (2) (mm) |

Tensile strength (N/5cm) |

Elongation (%) |

Tearing strength (N) |

Water permeability coefficient (cm/sec) |

Burst Strength (N) |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Color | Width (m) |

Roll length (m) |

*MD | *CD | *MD | *CD | *MD | *CD | Vertical direction |

Horizontal direction |

|||||

| AN160 B | Black | 2.1 | 100 | 160 | 1.5 | 1.3 | 490 | 340 | 55 | 60 | 155 | 175 | 1×10-1 | 5×10-1 | – |

| AN200 B | Black | 2.1 | 100 | 200 | 2.1 | 1.6 | 630 | 500 | 60 | 60 | 195 | 245 | – | ||

| AN300 B | Black | 2.1/4.2 | 50 | 300 | 3.0 | 2.4 | 1170 | 980 | 60 | 60 | 245 | 290 | – | ||

| AN400 B | Black | 2.1/4.2 | 50 | 400 | 4.0 | 3.0 | 1370 | 1170 | 60 | 60 | 340 | 390 | 800 | ||

* MD(machine direction)/*CD(cross direction)

* The measurement method shall comply with the following.

Tensile strength/tensile elongation: JIS L-1908

Tearing strength: JIS L-1096 (single tongue method)

Burst Strength: ASTM D 4833

Water permeability coefficient: JIS A-1218

Thickness (1): JIS L-1096 (pressure 7g/cm²)

Thickness (2): JIS L-1908 (pressure 20g/cm²)

The AN types are hydrophilically treated.