Roads

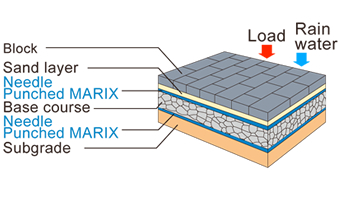

Interlocking block (ILB)

With its superb water permeability and filter performance, Needle Punched MARIX helps create comfortable puddle-free pavements with no unevenness.

Where Needle Punched MARIX is usedNeedle Punched MARIX precludes the loss of sand caused by rain water, thus preventing unevenness in the blocks.

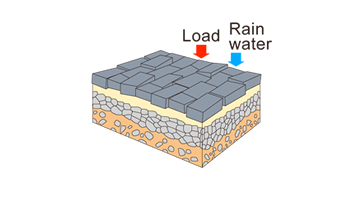

Where Needle Punched MARIX is usedNeedle Punched MARIX precludes the loss of sand caused by rain water, thus preventing unevenness in the blocks. Where Needle Punched MARIX is not usedSince Needle Punched MARIX is not used, the loss of sand is caused by rain water, leading to unevenness in the blocks.

Where Needle Punched MARIX is not usedSince Needle Punched MARIX is not used, the loss of sand is caused by rain water, leading to unevenness in the blocks.

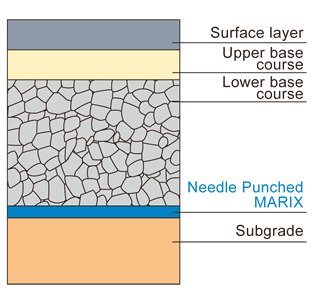

Pavement of soft subgrades

- With its filter performance (separation effect), Needle Punched MARIX prevents the base course material from mixing with soft subgrade soil, providing the ability to support the pavement.

With its filter performance (separation effect), Needle Punched MARIX prevents the base course material from mixing with soft subgrade soil, providing the ability to support the pavement.

Main applications and applicable Item No.

| Location | Construction method | AN060 | AN120 | AN160 | AN200 | AN300 | AN400 | AP110 |

|---|---|---|---|---|---|---|---|---|

| Roads sidewalks |

Embankment on soft grounds | ○ | ○ | ○ | ○ | |||

| Blocking layer | ○ | ○ | ○ | |||||

| Horizontal drain for embankment | ○ | ○ | ○ | |||||

| Crack prevention for overlay construction method | ○ | |||||||

| Separation for water permeable pavement | ○ | ○ | ○ | |||||

| Filter for underground seepage method | ○ | ○ | ○ | ○ |

Properties [catalog values]

| Item No. | Specification | Weight (g/m²) |

Thickness (1) (mm) |

Thickness (2) (mm) |

Tensile strength (N/5cm) |

Elongation (%) |

Tearing strength (N) |

Water permeability coefficient (cm/sec) |

Burst Strength (N) |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Color | Width (m) |

Roll length (m) |

*MD | *CD | *MD | *CD | *MD | *CD | Vertical direction |

Horizontal direction |

|||||

| AN060 W | White | 1.05/2.1 | 100 | 60 | 0.7 | 0.5 | 140 | 85 | 55 | 60 | 60 | 60 | 1×10-1 | 5×10-1 | – |

| AN120 W | White | 2.1 | 100 | 120 | 1.2 | 1.0 | 390 | 235 | 55 | 60 | 65 | 105 | – | ||

| AN160 B | Black | 2.1 | 100 | 160 | 1.5 | 1.3 | 490 | 340 | 55 | 60 | 155 | 175 | – | ||

| AN200 B | Black | 2.1 | 100 | 200 | 2.1 | 1.6 | 630 | 500 | 60 | 60 | 195 | 245 | – | ||

| AN300 B | Black | 2.1/4.2 | 50 | 300 | 3.0 | 2.4 | 1170 | 980 | 60 | 60 | 245 | 290 | – | ||

| AN400 B | Black | 2.1/4.2 | 50 | 400 | 4.0 | 3.0 | 1370 | 1170 | 60 | 60 | 340 | 390 | 800 | ||

| AP110 B | Black | 2.1 | 100 | 110 | 1.0 | 1.0 | 290 | 245 | 35 | 40 | 125 | 125 | – | ||

* MD(machine direction)/*CD(cross direction)

* The measurement method shall comply with the following.

Tensile strength/tensile elongation: JIS L-1908

Tearing strength: JIS L-1096 (single tongue method)

Burst Strength: ASTM D 4833

Water permeability coefficient: JIS A-1218

Thickness (1): JIS L-1096 (pressure 7g/cm²)

Thickness (2): JIS L-1908 (pressure 20g/cm²)

The AN types are hydrophilically treated.