Safety and Health Initiatives

At the Unitika Group, the Central Safety and Sanitation Committee is implementing health and safety activities aimed at eliminating accidents that require time off from work at all production sites and affiliates. We hold safety and sanitation managers meetings three times a year for those Group employees in charge of safety and sanitation.

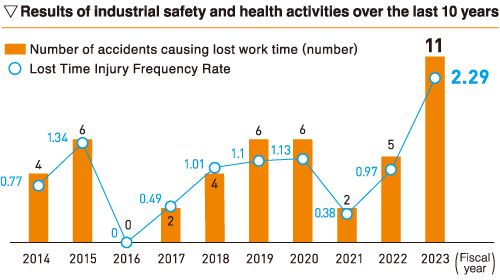

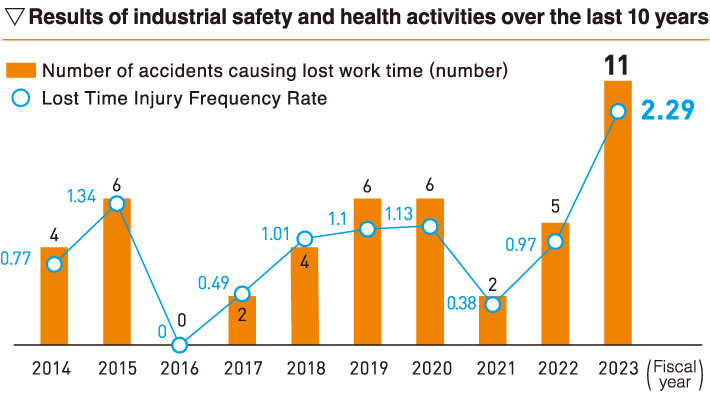

Unfortunately, in FY2023, there were 11 lost-time injuries, and the lost time injury frequency rate was 2.29, which we recognize as a very high value.

For this reason, we are conducting activities throughout the group to raise safety awareness by checking at each workplace whether "work procedures are being followed at the site" and "there are no deficiencies or omissions in the procedure manual. "

(Note)The reporting range

Before FY 2018: All main domestic production sites

FY 2019 to FY 2022: All domestic Group companies

FY 2023: entire Group, including overseas companies

KPIs of Priority Issues (Materiality)

Number of accidents causing lost work time (Until FY 2023)

FY 2023 actual results: 11 (entire Group, including overseas companies)

Lost Time Injury Frequency Rate (From FY 2024 onward)

FY 2030 target: 0.25 (entire Group, including overseas companies)

Dialogue with Employees

Each business site holds monthly meetings of Health and Safety Subcommittees at the department level and the Health and Safety Committee at the site level, where dialogue is conducted between employees and the top management of the site or department. The Committees share information on occupational accidents that have occurred within the Group, and report on matters identified during on-site patrols, the status of improvements, near-misses, and other matters. The Uji and Okazaki Plants also have “Hazard Simulation Training Facilities,” where new employees can simulate being entangled in or crushed by machinery and learn the importance of protective equipment.

Disaster Prevention and Readiness Initiatives

Central Disaster Readiness Committee

The Central Disaster Readiness Committee is chaired by man Resources and General Affairs Department, and consists of 13 members, including three Executive Officers; the general managers of the Legal & Compliance, Information Systems, and Procurement & Logistics Departments; the general manager of the Business Planning & Administration Department of the Group company Unitika Trading Co., Ltd., the office managers of the Osaka and Tokyo Head Offices, and the general managers of the Uji, Okazaki, and Tarui Plants.

The Committee is responsible for confirming the current status of disaster prevention organizations and activities, as well as for formulating and promoting the implementation of advance measures and providing guidance, in order to minimize damage to employees and facilities caused by disasters such as major earthquakes.

Strengthening of Disaster Prevention and Readiness Measures

To prepare for major disasters like the earthquake and tsunami that devastated Tohoku in March 2011, disaster readiness measures are crucial both to fulfill the basic mission of protecting the lives of employees, as well as to uphold the responsibility to stakeholders of continuing business activities. In July 2021, we revised the Unitika disaster prevention and readiness measures outline, and prepared a disaster prevention and readiness system and disaster control measures. Also in October 2023, the Central Disaster Readiness Committee held its FY 2023 Disaster Prevention Committee meeting to make the entire company aware of the importance of disaster prevention and readiness.

Additionally, as internal standards for managing safety at production facilities, Unitika has established a set of “pre-evaluation policies” on safety sanitation and environmental effects at new facilities. As a disaster readiness measure when creating or renovating facilities, a total of two rigorous inspections (during design and upon completion) are carried out in compliance with these standards.

Disaster Readiness Training

Unitika has reflected on the fire that occurred at the Uji Plant in January 2019, and we are reviewing overall the fire prevention system and working to prevent the recurrence of such incidents. We are also actively carrying out accidents and natural disaster training, as well as doing drills at production sites in the spring and autumn seasons of fire prevention activities.

At the Tarui Plant, 156 employees participated in an integrated disaster prevention and readiness drill on November 29, 2023. Fire drills using underground fire hydrants were also conducted along with earthquake simulation drills for notification, evacuation, and safety confirmation. At the Okazaki Plant, 477 employees participated in integrated fire prevention and disaster prevention drills on November 17, 2023. In addition to evacuation drills in preparation for an earthquake, we partnered with the head office squad and district squads to carry out drills in preparation for a variety of crises including emergency rescue, the outflow of chemicals, fire breakouts, and the confinement of employees. In addition, on September 21, 2023, a whole-site training was conducted for one of the three shifts (36 employees), and training was conducted by each department and group for the other shifts.

At the Uji Plant, 578 employees participated in a whole-site disaster prevention and readiness drill on March 21, 2024. Shakeout drills were conducted in each department, followed by evacuation drills to primary and tertiary evacuation sites, as well as a safety confirmation drill.

FY 2023 disaster prevention and readiness drill (Tarui Plant)

FY 2023 disaster prevention and readiness drill (Okazaki Plant)

Steam Eruption at the Uji Plant

In the early morning of October 10, 2023, a steam pipe ruptured at the Uji Plant’s power generation facility, causing steam to gush out. No one was injured in the accident, and the steam supply to the plant was restored six hours after the accident, with only a minor impact on production. Although the dispersal of a white substance due to the accident was confirmed, we promptly commissioned a third-party organization to conduct a health impact assessment, and received an opinion that no health effects are expected.

Subsequent investigation revealed that the accident was caused by an increase in temperature inside the boiler where the ruptured steam pipe was located. Therefore, we have added a function that automatically stops the boiler when the temperature inside the boiler rises, and we also conducted boiler accident education and training to prevent recurrence.

Preparation for Large-Scale Disasters

The Unitika Group has established the Protocols for Returning Home, which encourages employees to stay at their workplaces if trains and other public transportation stop running due to large-scale disasters. This is to prevent employees from having difficulties in returning home, and to prevent them from obstructing the operations of police officers and fire fighters. We are also making other preparations such as storing disaster equipment, supplies, drinking water and preserved food. We have also established a system that allows us to handle requests for support from local residents in surrounding neighborhoods and for cooperation from local governments.